Porthole Die Stress checking.

Views: 29 Author: Site Editor Publish Time: 2021-12-21 Origin: Site

Porthole Die Stress checking.

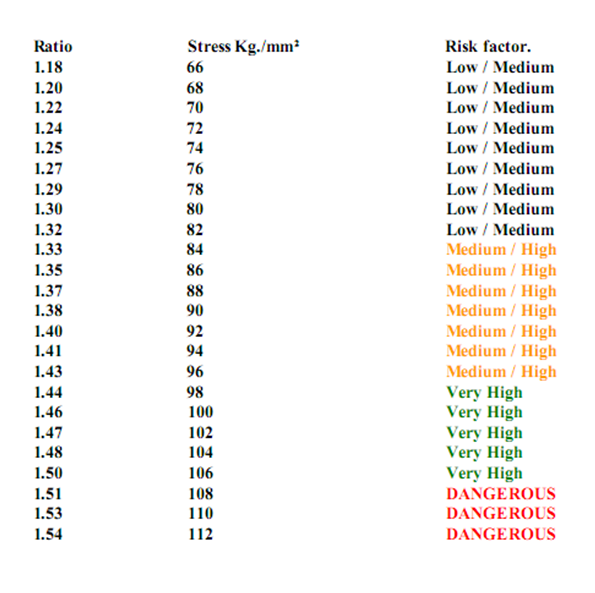

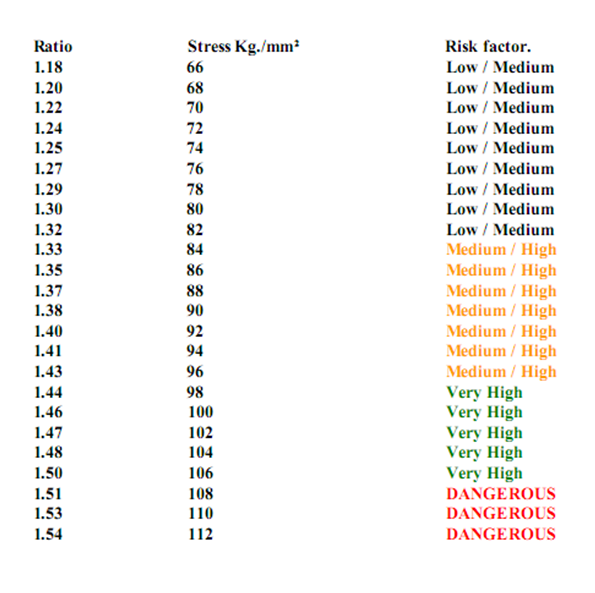

This is a quick and simple method used to check if a given die design has sufficient

strength and the likelihood of failure of the die during the die’s life time. This system is

based on the calculation that is used by the Die-maker and has been adjusted to a table

form. This will give a quick and easy way to get a forecast for the life of the die. The

figures used in this system are based on the stress limit for a typical die steel ( H13 or

similar ) to be 90kg / mm². The length of the span of the bridge (usually diagonal) is

denoted by “L” and the height of the web of the bridge is denoted by “H”. The ratio of L H

has been tabulated and the corresponding stress can be read opposite together with the risk

factor.

Obviously figures that outside of those given in the table are self explanatory and as most

designs of die will have stresses that have been calculated to fall in the area of below

90kg./mm². This method is useful as a checking method that may be of special interest

when looking at a die that is very complex in nature, construction and designs

characteristics.

The Die Maker should be m ore than happy to supply any information to you concerning

the stress calculation system that they use and the particular formula for calculation. These

are readily obtained via the net, but it is always much simpler if the calculation is

simplified by working through an example. The stress checking is for the design

parameters of a web or bridge, but, the tool is under extreme loading internally as well.

Consideration should made for this in respect of the minimum thickness of the outside of

the tools diameter and whether the tool is for a profile with an extremely high Extrusion

Ratio.

Should this be the case then a larger diameter tool should be considered, also if it is found

that a tool is distorting on its outside diameter and possibly seizing in the die holder / die

ring then changes should be considered.